Introduction

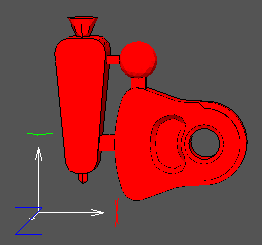

Module Master is the preprocessor of CSS PoligonSoft designated for setup of three-dimensional models (GM) for simulations in the processor modules (solvers) Euler, Fourier, Hooke etc.

Preparation to the simulation consists of:

- preparation of the computational area (or GM);

- preparation of the casting materials properties;

- preparation of the mold materials properties;

- preparation of the heat transfer parameters;

- preparation of other data depending on the task being solved.

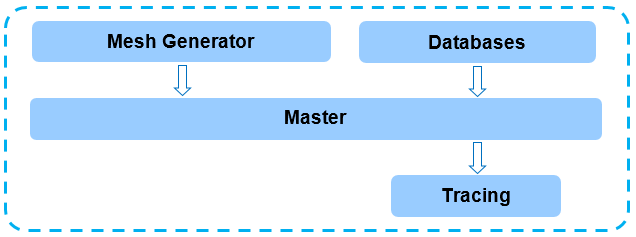

All these actions are performed in the modules of PoligonSoft unified in the preprocessors group.

PoligonSoft Preprocessors

This chapter describes the process of simulation preparation depending on the case. The Preparing the Modeling Area section describes the general principles of GM preparation, the possibilities of Master module are discussed in details. Calculation of temperature fields in a casting and a mold is the main task of modeling, regardless of the casting technology and the formulation of the problem. Therefore, the steps described in this section are required to prepare any calculation. The next sections describes how to set-up the cases of filling, radiation heat transfer, simulation of the shrinkage porosity and stress.

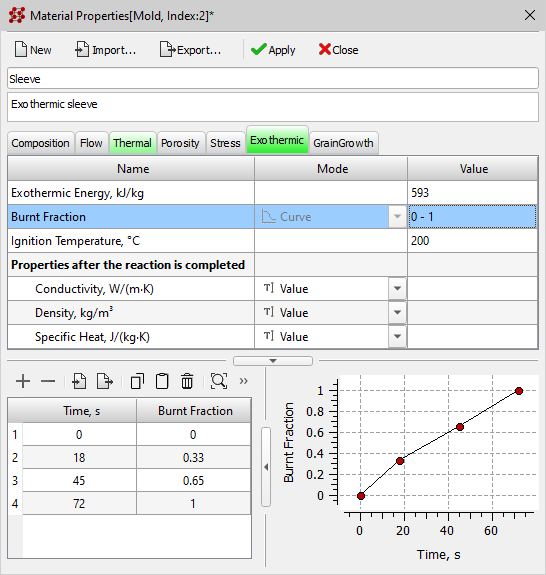

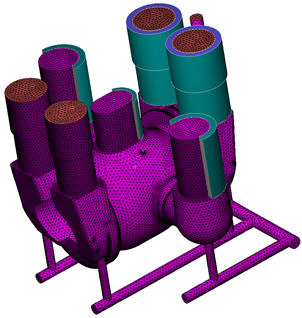

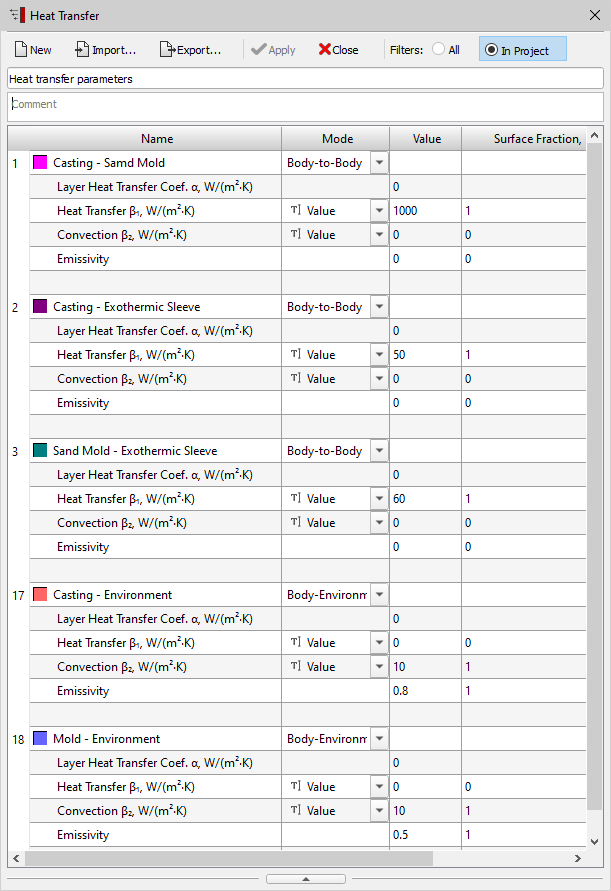

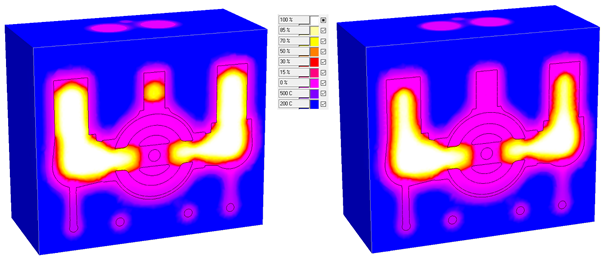

Next there is the description of the irregular modelling tasks, such as: exothermic sleeves, virtual mold and simulation with the non-coincident meshes and the description of the task settings of the simulation of a special casting technologies (centrifugal casting, high pressure die casting (HPDC), continuous casting and so on).

At the end of the chapter, there is the detailed description of the work with PoligonSoft «databases.

To start the calculation, the user should perform the following actions in the Master module:

- import the finite element model of the computational domain, created in the mesh generator;

- set the right orientation of the model;

- indicate the belonging of each body of the model to a casting or mold;

- set casting alloy and mold materials properties;

- describe the boundary conditions, for example, set the parameters of heat transfer between the bodies of the model and with the environment;

- determine the initial conditions for the calculation, for example, the initial temperatures of all bodies;

- set other parameters in accordance with the simulated technology: the location of the melt supply and its speed, the movement or rotation of bodies, etc.;

- run calculation.

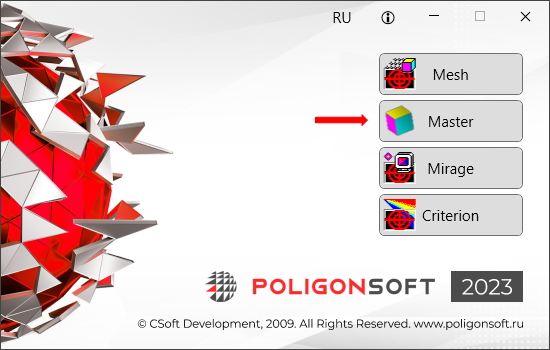

The module starts from the main window with the Master button, or the same command from menu Preprocessor.

Start of the Master Module

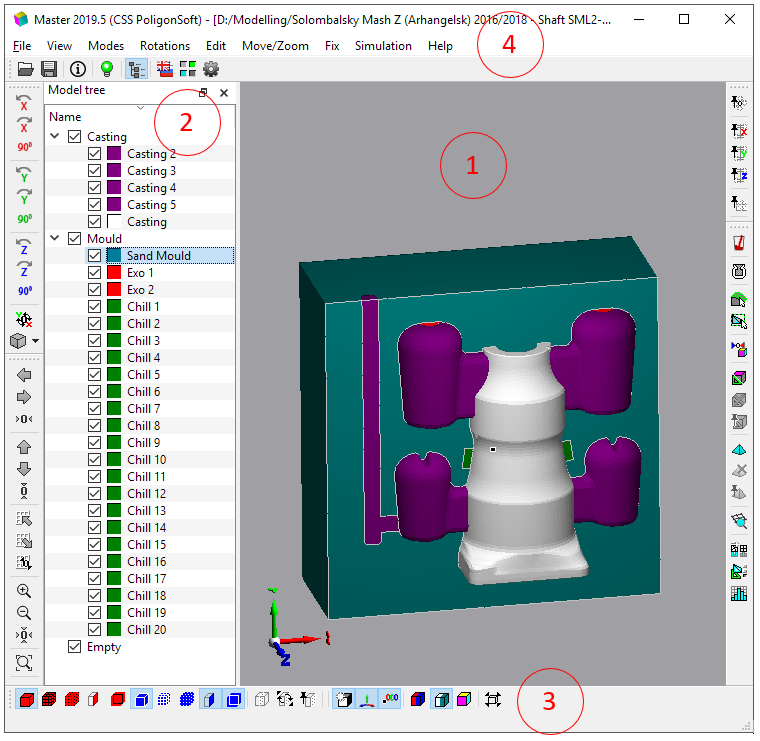

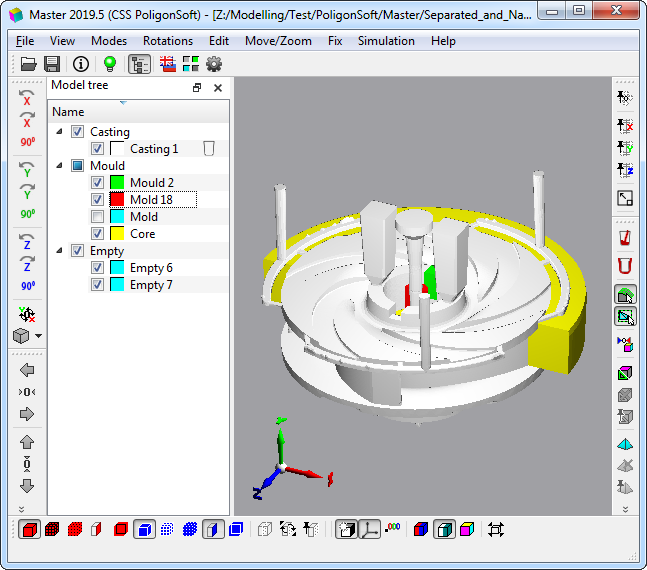

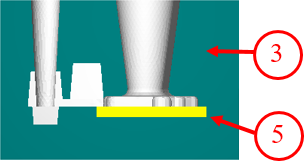

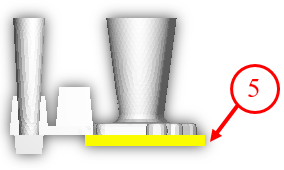

The main part of the module window (see the figure below) is occupied by the working area, where the GM is displayed (1). On the left is the Model Tree (2), which displays a list of GM volumes. The Model Tree allows you to control the visualization of the GM and set the most important parameters of the computational domain. Toolbars (3) are installed on all sides of the module window. The menu bar (4) is also installed at the top of the window.

When working with the program, you can use both the commands of the main menu in the upper part of the window, and the buttons on the toolbars. Almost all items of the main menu are duplicated by the corresponding buttons on the toolbars. Further, when describing the functions of the module, their call will be indicated only using the buttons on the toolbars, implying that there are corresponding menu items, as well as hotkeys (for some commands) indicated in the names of menu items and button tips.

Master module window

Basic concepts: Volumes, Types, Indices

The main task of module Master is to provide to the user the possibility to designate the groups of the finite elements with the different properties and their faces with different characteristics. Such identification of the faces and elements is the base of simulation process.

VOLUMES. When loading the finite – element mesh, “Master-3D guided by the geometry topology and indication of the files in the mesh groups the finite elements into the volumes. More often, the dividing into volumes, this or the other way, is indicated in the original mesh and, as a rule, partially due to the dividing into the volumes of the original geometric model (even before the dividing to the finite elements), and partly the consequence of the assignments when generating the mesh. The finite elements (and their faces) grouped into the volumes are automatically assigned some indices and types. (For more details about types and indices, see below.) Most likely, the procedure of primary assignment of the indices (types) of the finite elements will be done by the program in the way that the user would not like. It is important, however, that a certain number of autonomous volumes are separated in the whole mesh, within which the properties of all finite elements are the same. Accordingly, the main task of the user is to edit the primary assignments or those assignments that have been made earlier (if the mesh is loaded in the PoligonSoft format). In the process of editing the mesh parameters, it is also possible to create new volumes. For more information on creating new volumes, see the section on editing the elements indices in an arbitrary areas.

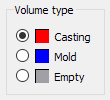

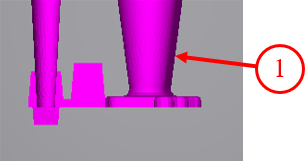

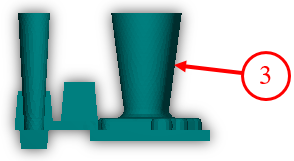

TYPES (“cast/mold/empty”). It is obvious that the finite elements being in the casting group have the specific properties and are the elements of one type and the finite elements being in the mold group relate to the other type. How to assign the types is described in the Editing Volume Types and Indices section.

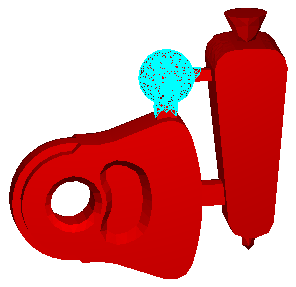

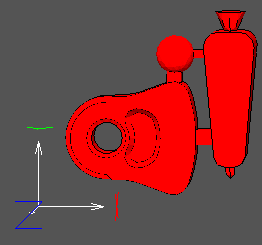

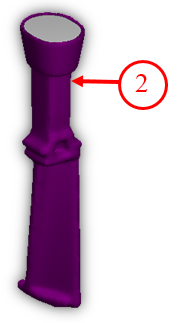

When visualizing the types, PoligonSoft usually uses the red color for casting, and blue for the mold. In addition, the "Master-3D" module can use one more type - the so-called "disconnected" or "empty" type. This type is used if it is desired that the area of such “empty” type is not included in the final geometric model. Although volumes of this type are not rendered, but for color indexing of the "empty" type, the dialog boxes of the "Master-3D" module use a grey color.

Volumes Types

ELEMENTS (volumes) INDICES. In addition, both the casting and the mold can be non-uniform, i.e. not all finite elements entering into them necessarily have the same properties. Thus, several materials can be used simultaneously in the molds; they can have the cores, cooling plates, etc in their composition. In it’s turn the casting being monolithic and homogeneous by the physical properties, may have the areas within itself that are distinguished, for example, by the value of the initial temperature. In order to take into account all these differences, the elements are grouped together and assign the same index number to the elements of the group.

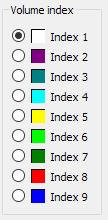

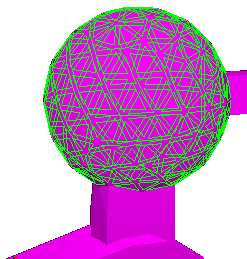

In total, there are 9 elements indices and they are numbered from 1 to 9. The PoligonSoft has a certain color scheme of the element and color index correspondence used for the visualization of the elements (volumes).

Volumes indices

The element index (and its color) means that some condition or property (physical parameters, temperature, etc.) will be assigned to this group of elements. These conditions and properties must also be defined in the Master module by connecting the appropriate databases, templates and process conditions. For example, for volumes of the "mold" type, the index of the element always determines the its material. The properties of this material will be assigned to this volume when connected mold material properties to the model. At this stage, it is advisable to connect one of the technological process templates to the Master module in order to view ready-made sets of mold materials and determine volume indices. This is done in the Start Simulation and Parameters window on the General tab in the Mold Properties line or on the Project Overview tab in Master module window.

Accordingly, if the same properties or conditions are assigned to elements with different indices, then these elements will behave in the same way during simulation. Such an indexing system makes it possible to economically and efficiently set a wide variety of simulation conditions, for example, two domains of identical materials can easily be assigned the same thermophysical properties, but different initial temperatures.

When the model is first loaded into the Master module, the volumes are consecutively numbered, i.e. the first volume gets index 1, the second one gets index 2, and so on. If there are more than 9 volumes in the model, the tenth volume will again receive index 1, and so on. How to assign the element indices is described in the section on editing the indices of volumes and arbitrary areas.

BOUNDARY (elements faces) INDICES. Like the elements themselves, the characteristics of the faces of the finite elements can be different: one thing is the faces between the casting and the mold, and quite another is the face between the mold and the external environment. Therefore, one boundary index unites the faces forming the boundaries (surfaces) that share the volumes of finite elements with the same properties. The characteristics of these faces reflect the processes (for example, the heat transfer) occurring during transfer from one part of the simulation object to its other part (for example, from the cast to some mold volume). In this case, the boundary indices are assigned only to the surfaces limiting the volume of the casting and to the surfaces limiting the volume of the mold. The faces of the elements contacting the faces of the "own" type (i.e., "casting-casting" and "mold-mold") cannot be specially indexed because it is not assumed that there will be the jump in the simulated function on the boundary of their contact (for example, the temperature distribution) and, consequently, there is no need to indicate the characteristics of the transition process through such faces. Such faces have automatically zero index, they are not visualized and inaccessible for assigning the boundary indices. How to assign the boundary indices is described in the section on editing the boundary indices.

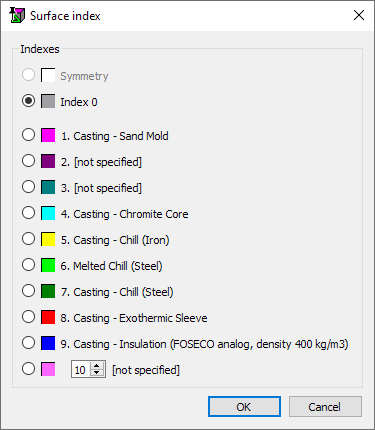

In total, there are 19 boundary indices, and they are numbered from 0 to 18. In contrast to the element indices, the index numbers of the faces have more rigid semantic load. In PoligonSoft, some rules are adopted for assigning the boundary indices, which cannot be violated.

In particular, zero indices are assigned to the boundaries of symmetry, internal boundaries and surfaces with zero normal flows (from the point of view of thermal, diffusion, filtration, electrical, etc. flows, all these are the boundaries of the same type).

The indices from 1 to 9 can be assigned to the boundaries between the casting and the mold. In this case, even if in fact there is nothing beyond such a boundary, then PoligonSoft will "know" that beyond this boundary is meant the existence of some conditional "infinite" mold. The material properties of such effective mold will be used in accordance with the same index that this boundary has. (This rule is valid both for the boundaries of the casting and for the boundaries of the mold - in any case, the mold will be considered as an effective continuation). More details of the simulation task with a virtual mold are provided in Virtual Mold section. This indices also can be assigned to the boundaries between the casting and the ambient with assigned temperature.

Finally, the indices from 10 to 18 can be assigned only to the boundaries with the medium. In this case, if in fact there is a certain body behind such as a boundary, then PoligonSoft will still assume that this is the boundary with the environment (this can be used if, for some reasons, it is necessary to "disconnect" the connection between the casting and the mold in the simulation).

As for the difference between the numbers within the listed groups, just as for the indices of the elements, these numbers will acquire quantitative physical characteristics only after some physical parameters are assigned to them, for example, the parameters of the boundary heat transfer. This assignment is made in the Master module when one of the process templates is connected. This is done in the Start Simulation and Parameters window on the General tab in the Heat Transfer Parameters line. As for element indexes, for faces in PolygonSoft, a certain color scheme is adopted, which is used when visualizing borders (see the figure below).

Boundaries Indices

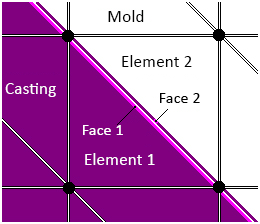

You should pay attention to the fact that there are always actually two faces on any boundary between the elements - the face of one element and the face of another element.

Boundary between the bodies (elements)

Accordingly, each of these faces can formally have its own index. In the usual case, either the numbers of these indices, or the parameters assigned to the numbers of these indices should be equal, since from the physical point of view, this is the same boundary. However, there are the specific cases when it is necessary to specify different boundary parameters from different sides of the same boundary. (In this case, the casting will be associated with the mold by one parameter, and the mold with the casting by the other.) In any case, when assigning the physical parameters to the boundary indices, it should be remembered that the boundary indices from different sides of the same boundary can be different.

At the initial loading, all faces are assigned the indices according to the standard rule, a so-called the STANDARD boundary indices "by default". This standard assignment is performed as follows. All boundaries of the "casting-mold" type are assigned the indices 1 and 2, at that from the side of the casting 1, and from the side of the mold 2. Accordingly, in the usual case, when assigning the boundary parameters of the heat transfer coefficients, for example, the equal values should be assigned to the indices 1 and 2, since in fact, this is the same boundary between the casting and the mold. The boundaries of the casting with the environment are assigned the index 8, and the mold boundaries with the environment are assigned the index 9. However, as indicated above, the volume belonging to the casting or the mold after the primary designation will most likely require the correction, and then the initial designation of the boundaries will become unsatisfactory. Therefore, after editing the types of the volumes to simplify the operation, it makes sense to repeat the standard designation procedure. How to do it is described in the section on editing the boundary indices. In the future, you can edit this standard assignment, as it is necessary for a specific case, in accordance with the assignment rules described above. For example, some of the outer boundaries, which are formally interpreted as the boundaries with the environment, can be in fact the symmetry boundaries and, accordingly, they must be set by a zero index.

In addition to the operations for importing the mesh, assigning the indices and the types, the "Master-3D" module has the possibilities for different representations of the finite element model, its scaling, rotation, section, size determination of various parts of the geometric model, etc. In addition, there are a number of special functions for determining and improving the quality of the finite element mesh, searching and correction the degenerated elements, and other procedures, the links to which are available in the list of the sections of the description of this module.

Toolbars

This section provides a complete listing of toolbars commands . As mentioned above, almost all the menu items are duplicated by the corresponding buttons on the toolbars. Each command is given a short description and a link to the corresponding section.

Standard Toolbar

The most common functions (loading GM, recording GM, etc.) are concentrated on the Standard toolbar in the upper part of the preprocessor window (see the figure below)

Standard Toolbar

|

The Open Geometry (Ctrl+O) button is used to load the mesh model in different formats. See Loading and saving the model section for more details. |

|

The Save Geometry (Ctrl+S) button saves the geometric model with all the assigned conditions and calculation parameters in the PolygonSoft format with the g3d extension. See Loading and saving the model section for more details. |

|

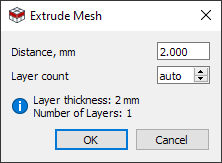

The Model Information (Ctrl+I) button opens a window that contains information about the loaded geometric model. See Model Information section for more details. |

|

The Start Simulation and Parameters (Ctrl+R) button opens a window where all the required simulation data is set and the calculation starts. See Simulation chapter for more details. |

|

The View Results button launches the postprocessor to view the calculation results. See Viewing Results chapter for more details. |

|

The Model Tree button enables displaying the model tree on the left side of the Master module window. For information on using the model tree, see Editing Volume Types and Indices section. |

|

The Language (F3) button changes the interface language from Russian to English and vice versa. |

|

The Special Colors button opens the Master module settings window, where you can set the background color of the workspace, casting mesh, mold mesh, section plane color, border and element mark colors. See Special Colors. section for more details. |

|

The Settings (Ctrl+Alt+S) button opens a window that contains all the parameters that control the preprocessor work and its individual functions. See Module Settings section for more details. |

Process Toolbar

Functions and tools associated with the case setup (materials, process parameters, boundary and initial conditions) are called by buttons on the Process toolbar (see the figure below), which by default is located along the top border of the Master module window.

Process Toolbar

|

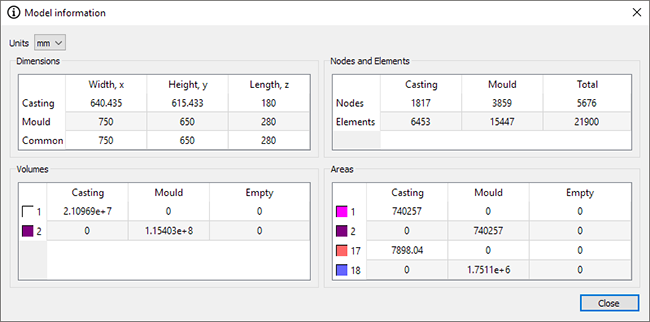

The Inlets button opens a dialog where you can specify the locations of the melt inlets into the mold, their sizes and parameters. See Melt Inlet section for more details. |

|

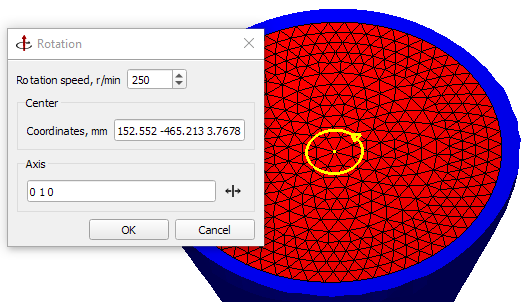

The Rotation button opens a dialog where you can set the speed and direction of rotation of the model during centrifugal casting. See Centrifugal Casting section for more details. |

|

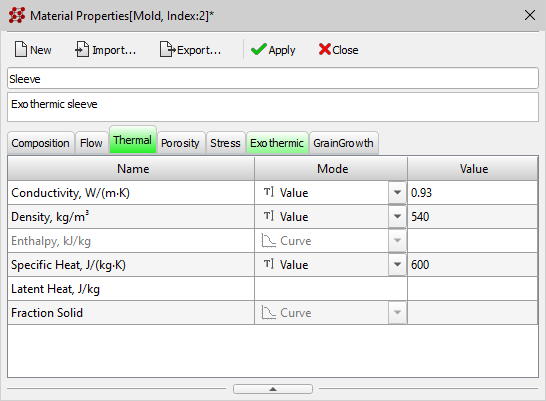

The Material Properties button opens the editor where the materials used in the calculation are created and edited. See Material Properties section for more details. |

|

The Heat Transfer button opens the editor where heat transfer parameters are created and edited at the boundaries between volumes (body-body) and at external boundaries (body-environment). See Heat Transfer Parameters section for more details. |

|

The Temperature Modes button opens the editor where the temperature modes of the casting and mold volumes are created and edited. See Temperature Modes section for more details. |

|

The Translation button opens an editor where modes for moving casting and mold volumes are created and edited. See the Translation Modes section for more details. |

Edit Toolbar

The largest number of special functions of the Master module are called by the buttons on the Edit toolbar, which by default is located along the right border of the Master module window.

Edit Toolbar

|

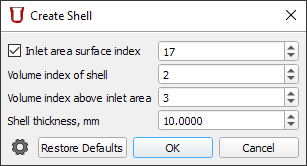

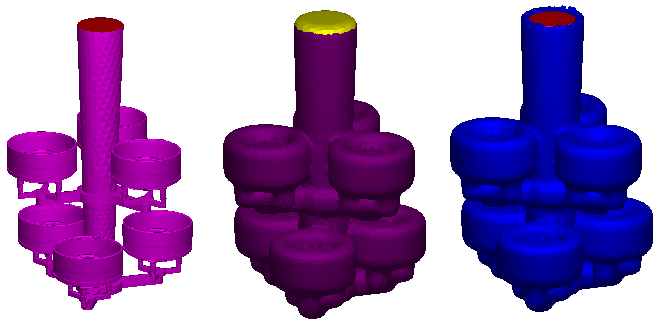

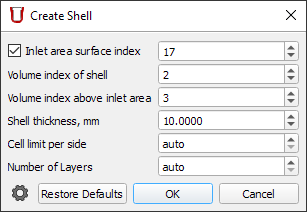

The Create Shell button opens a dialog for creating a shell of a given thickness around the selected bodies. See Shells Creation section for more details. |

|

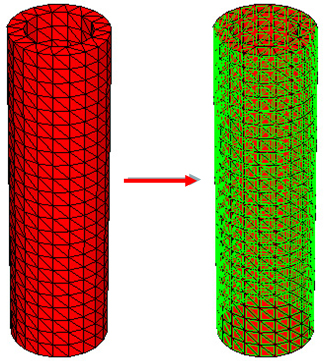

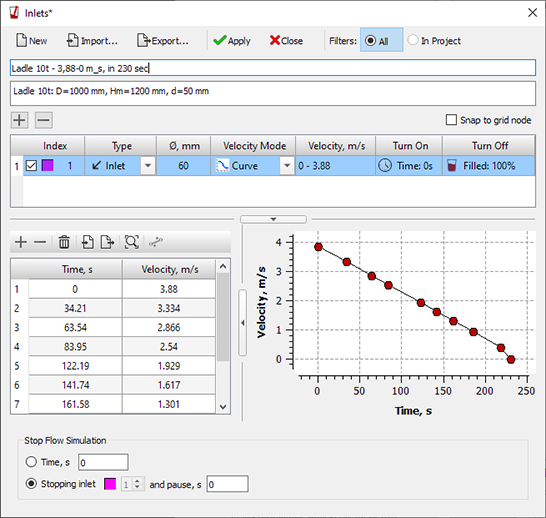

The Extrude Mesh button opens a dialog for creating new volumes by extruding a surface mesh at a specified distance. See New Volumes Creation (Extrude Mesh) section for more details. |

|

The Select Contiguous button turns on the surface selection mode. See Editing Boundary Indices section for more details. |

|

The Select Elements by Frame button turns on the frame selection mode. See Editing the indices of the elements in the arbitrary areas section for more details. |

|

The Set Default Boundary Indices button assigns default boundaries for the entire GM. See Editing Boundary Indices section for more details. |

|

The Select Boundaries button opens a dialog for selecting boundaries by index. See Editing Boundary Indices section for more details. |

|

The Deselect All Boundaries (Ctrl+G) button deselects all the selected boundaries. See Editing Boundary Indices section for more details. |

|

The Assign Boundary Index button opens a dialog for assigning an index to the selected boundaries. See Editing Boundary Indices section for more details. |

|

The Select Elements button opens a dialog for selecting elements by index. See Editing the indices of the elements in the arbitrary areas section for more details. |

|

The Deselect All Elements (Ctrl+E) button deselects all selected elements. See Editing the indices of the elements in the arbitrary areas section for more details. |

|

The Assign Volume Index button opens a dialog for assigning an index to the selected elements. See Editing the indices of the elements in the arbitrary areas section for more details. |

|

The Check Mesh Quality button checks the mesh quality according to various criteria and opens a dialog for viewing the report and correcting bad elements. See Mesh Quality Control section for more details. |

|

The Refine Mesh button performs a shift of mesh nodes to improve its quality. See Mesh Quality Control section for more details. |

|

The Split Elements button opens a dialog for choosing an algorithm for remeshing the selected mesh fragment. See Mesh Quality Control section for more details. |

|

The Mark Parameters button opens the preprocessor settings window for selecting parameters and display styles for selected elements and boundaries. See Mark Parameters section for more details. |

|

The Mesh Quality button shows a histogram of the deviation of mesh elements from an ideal tetrahedron. See Mesh Quality Control section for more details. |

Transformation Toolbar

Commands changing the geometric model: its orientation, shape, size, position, etc., are located on the Transformation toolbar (see the figure below).

Transformation Toolbar

|

The Fix Rotation button rotates the coordinate system to its base position (front view), and changes the orientation of the model in space. |

|

The Reflect by X button flips the geometry around the X axis. |

|

The Reflect by Y button flips the geometry around the Y axis. |

|

The Reflect by Z button flips the geometry around the Z axis. |

|

The Scale button resizes the model. |

|

The Copy/Move button copies or moves the visible bodies of the model in the given direction. |

|

The Measure (F4) button opens a tool for measuring the distance between two given points. |

For more details about each command, see the Change Model Orientation, Position and Size section.

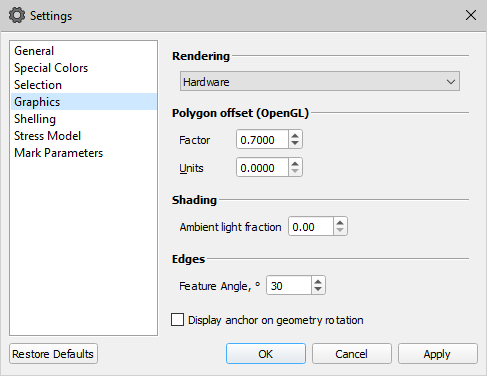

Module Settings

|

Settings button on the Standard toolbar opens a window that contains all the parameters that control the work of the preprocessor as a whole and its individual functions. To open the settings window, you can use the key combination Ctrl + Alt + S (see the figure below). |

Master module Settings window

The settings are grouped in tabs, according to the list on the left side of the window. To take effect, you should click the Apply button. However, as a rule, these settings do not require constant adjustment. The default values set the maximum comfort when working with the geometric model. The models settings and settings for some special functions specified in this window will be described further in the corresponding sections. This section describes settings that affect the preprocessor operation.

To return to the default module settings, click the Restore Defaults button in the lower left corner of the window and then confirm the selection with the OK button. All module settings are reset at the same time.

General

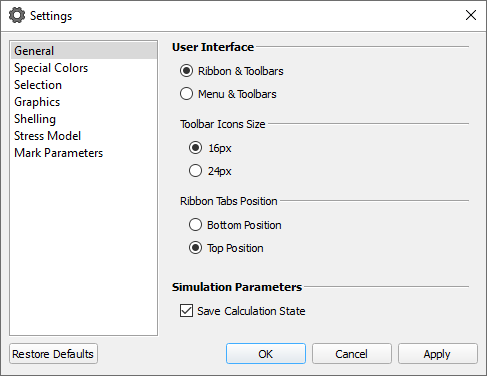

The General tab contains user interface settings (see the figure below).

- User Interface Group. Sets the general appearance of the user interface - tabbed ribbon menu or classic menu. In both cases, you can additionally use toolbars.

Default value: Ribbon and Toolbars. - Toolbar Icons Size Group. Specifies the size of buttons on toolbars.

Default value: 16px. - Ribbon Tabs Position Group. Specifies where the ribbon tabs will appear above or below the ribbon.

Default value: Top Position.

General Tab

Simulation Parameters Group

- Save Calculation State. The parameter determines whether calculation state files with the dump extension will be created and updated in the DUMP folder. These files are updated every time results are written and can take up significant disk space. With their help, you can continue an interrupted calculation from the moment of the last entry. When this option is disabled, the DUMP folder and the files in it are not created. In this case, the calculation can be continued only from the moment the current solver is launched (from the beginning of filling, solidification, etc.). For more details, see the Continuing an Interrupted Simulation section.

Parameter is enabled by default.

Special Colors

|

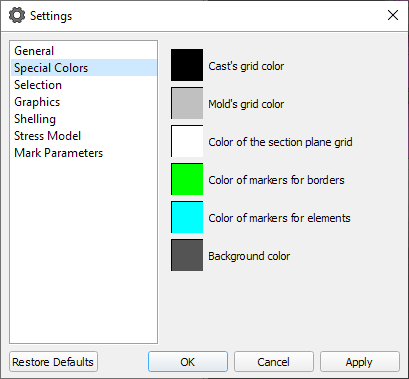

The Special Colors button on the Standard toolbar opens the Settings window on the corresponding tab where the user can set the background color, casting mesh color, mold mesh color, section plane color, edges and element label colors (see the figure below). |

Special Colors Tab

To set a color, click on the corresponding colored square. The standard MS Windows Color Picker window will open. Having set the desired color in it, you should click OK button to return to the window for setting Special Colors. After making all the changes, click the OK button.

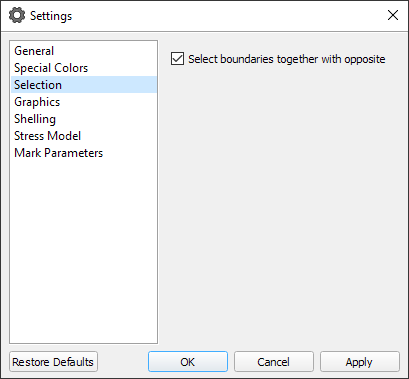

Selection

There is only one setting on this tab so far.

- Select boundaries together with opposite. If the parameter is enabled, then when selecting internal mated boundaries of the "cast-mold" or "mold-to-mold" type, a new boundary index is assigned simultaneously to both of its sides. For example, if you assign a new index to a casting-chill boundary on the chill side, the casting-side boundary will automatically get the same index. When this option is off, you can assign different indexes to mating boundaries.

Parameter is enabled by default.

Selection Tab

Mark Parameters

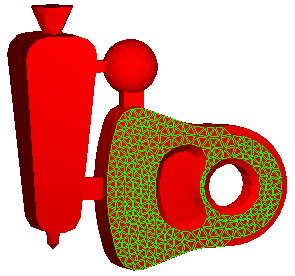

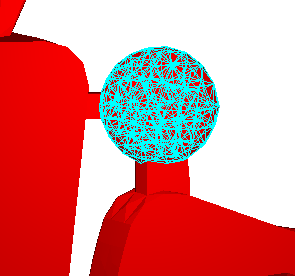

The visualization of the selected (marked) elements or their external faces is performed using marks - highlighting the edges of the faces and / or a point in the center with color (see the figure below).

|

|

Boundary selection result |

Element selection result |

An example of visualization of marked elements and faces

|

The color of element and face marks is set in the Settings window, which can be opened by pressing the Special Colors button on the Standard panel (for more details, see the Special Colors section). |

|

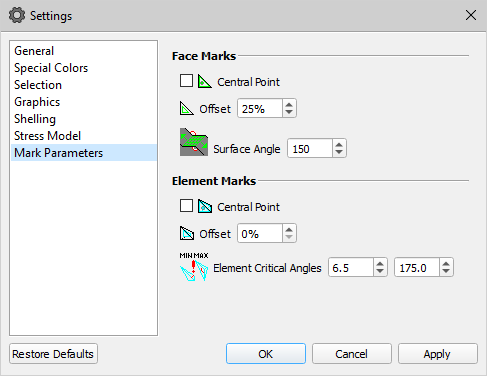

The style of marks can also be changed by the user. To do this, you can use the Mark Parameters button on the Edit toolbar. The Settings window will open, where the Mark Parameters tab contains the settings that determine the appearance of the element and face marks (see the figure below). |

Mark Parameters Tab

This tab contains two groups: face marks options and element marks options. With their help, you can achieve the most convenient marks visualization.

|

Central Point options draw a point at the center of the marked triangle or element. The parameter is disabled by default. |

|

The Offset options control the visual gap between selected objects. When the gap is zero, the edges of the object are painted directly, and when the gap is increased, the edges of the marks are drawn inside the selected object. Specified as a percentage. |

|

The Surface Angle parameter specifies the criterion for determining whether adjacent feature faces belong to the same surface. If the dihedral angle between adjacent faces is equal to or greater than the specified value, the faces are considered to be on the same surface. This allows you to select faces not element-by-element, but immediately with surfaces. For example, if you set the parameter equal to 180°, the faces that lie in the same plane will be selected, and if the parameter value is 0°, all the edges of the object are selected. The parameter is set in degrees from 0 to 180. The default value is 150°. |

|

The Element Critical Angles parameter specifies the minimum and maximum dihedral angles in degrees. These values are used when analyzing the finite element model for quality. The default limit angles are set to 6.5° and 175°, which usually do not need to be changed. For more information on checking the mesh quality, see Mesh Quality Control section. |

Preparing the Modeling Area

Loading and saving the model

The creation of three-dimensional geometric model and its dividing to the finite elements are the complex processes requiring the specialized software. The programs performing the dividing operation save the results of its work in the original file formats. That’s why all models prepared in the external mesh generators should be converted from their formats to the internal format of PoligonSoft.

Initially, the working field of the program is free, and most of the buttons on the toolbars are unavailable. And this is natural, since the source file containing the geometric model (GM) has not yet been loaded into the program. Recall that from the point of view of numerical simulations by the finite element method, the geometric model is a finite element mesh.

|

In order to load the GM, you should click the Open Geometry, button, usually located in the upper left corner of the window on the Working commands toolbar. You can also use the drop-down menu of the "File" menu item or the Ctrl+O key combination. |

Note that the menu items duplicate all buttons on the toolbars. In the description we will go from the buttons of the toolbars, without mentioning each time about the presence of a similar item in the submenu and the hot keys noted there.

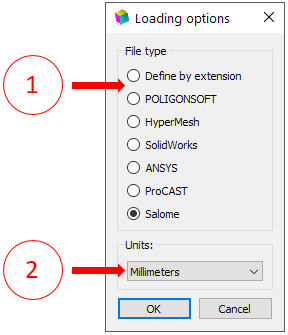

After clicking the Open Geometry File button, the Loading Options window will open.

Loading Options Dialog

In this window, use the radio buttons to select the file type (1) that you want to download. The possible file types cover formats of almost all modern programs intended for dividing the geometric models into the finite elements: FEMAP, HyperMesh, NASTRAN, PATRAN, ANSYS, CADDS, NX, CATIA, ProCAST and SALOME (supplied with PoligonSoft). Selecting the type "POLIGONSOFT" means that it will load a file that has already been saved in PoligonSoft format.

Then you can specify the units in which the coordinates of the nodes in the downloaded file (2) are recorded or specify the unique scale factor. In various CAD-systems and mesh-generator programs, the coordinates of points of the geometric objects are specified in different units of length: millimeters, inches, meters, etc. PoligonSoft relies on the SI system, and measures all coordinates in meters. Therefore, in order to observe the true size of the geometric model, the corresponding coordinate resimulation should be performed. For example, in the transition from millimeters to meters, all coordinates should be multiplied by 0.001. To change the current scale factor, you should normally set the text cursor in the input field and enter the corresponding number on the keyboard. To check how the program responded to the introduction of the scale factor, you can check the size of the model on the Information Panel. (It is called by a special button, which will be described below.)

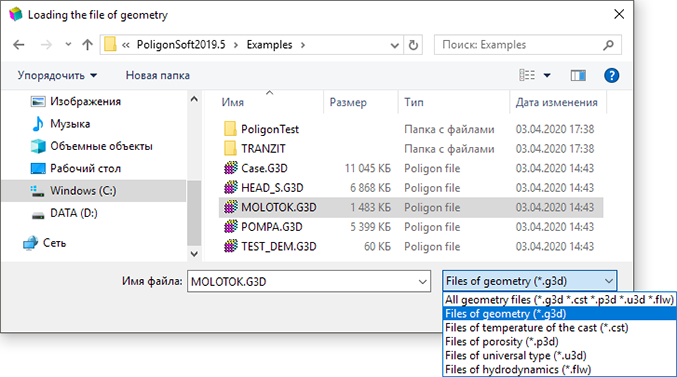

After clicking the OK button, Open Geometry File window will open, in which you can find the file to be loaded on the disks.

Open Geometry File Window

The built-in filter contains a list of file types available for download. When loading files of the PoligonSoft type (extension * .g3d), this list will also contain file types containing the results of calculating different fields (temperatures, porosity, flow rates, etc.), since they also partially or completely contain the geometric model. For example, the temperature file (* .cst) contains the complete GM of castings and molds, while the porosity (* .p3d), fluid dynamics (* .flw), and universal file (* .u3d) contain only the GM of castings.

If you select the Define by Extension radio button in the Loading Options window, it will be possible to load any file with a finite element mesh, since the filter All files (*. *) will be used. When loading, the units of length previously set for the selected file type will be used. If you try to download a file that does not match any of the used formats, an error message will be displayed.

Files can also be loaded by dragging them onto the working area of the preprocessor window.

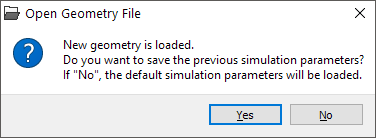

In PoligonSoft there is a possibility of inheriting the parameters specified during the preparation of the previous simulation. This is very convenient when you need to simulate the same casting, but with a different gating-feeding system under the same (or close to the same) conditions. In such cases, most of the parameters such as: casting alloy, mold materials, heat transfer parameters, initial temperatures, etc. remain unchanged and can be translated to a new geometric model. Therefore, after loading the mesh, a message is displayed (see the figure below), in which it is proposed to apply the parameters of the previous calculation to the loaded geometry (Yes button), or load the default calculation parameters (No button).

Selecting the option for loading simulation parameters

As a rule, the image of the object is loaded in the mode of displaying the surfaces of the casting and the mold with the cross-section of the mold in the XY plane. However, you can easily change this mode, you can orient the model in a convenient way, draw the sections, etc. For details on how to control the representation of a simulation object, see the section on the Common Elements of 3D Modules.

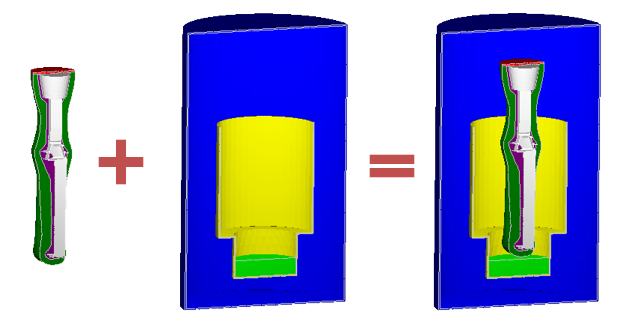

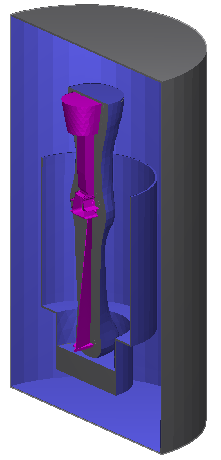

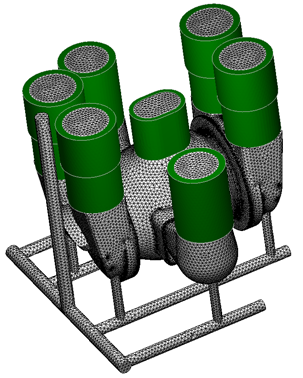

In the preprocessor Master it is possible to add other GM from previously created geometry files to the loaded model. This can be convenient if some of the GM bodies involved in the calculation do not change in the process of technology development. For example, when simulating vacuum casting, a furnace with heaters is involved in the calculation. This GM can be added to any model of the casting block that is planned to be filled in this furnace (see figure below). Of course, both GMs must be performed in a single coordinate system. To add a GM, select the Append Geometry ... command from the File menu and load the required file.

Example of adding a furnace model to a casting model

A list of previously opened geometry files is stored in the File-Recently Open Files menu.

|

The Save Geometry command will save the geometric model with all the assigned conditions and calculation parameters in the PoligonSoft file with the g3d extension, in which it is ready for calculation. To call the command, you can use the key combination Ctrl+S. |

After clicking the Save Geometry button, a standard dialog will open, in which you can specify a file name and specify its location on disk. By default, in the Save Geometry dialog, in the File Type field, the "Geometry Files (* .g3d)" filter is set. When saving with this filter, a geometry file will be saved in the specified location and a DATA folder will be created, into which files with additional data necessary to start the simulation will be written. If you need to run the calculation on another computer or in a different folder, copy the g3d file and the DATA folder to a new location, open the geometry file in the Master module and all the simulation parameters will be updated.

It is also possible to save the geometry file without additional data, i.e. only a finite element model without reference to the given simulation parameters. To do this, in the save dialog, change the file type to "Mesh only (* .g3d)". In this case, only the g3d file will be saved, no DATA folder will be created.

Change Model Orientation, Position and Size

In PoligonSoft, the gravity vector is always directed against the Y-axis and this is important for the correct calculation of shrinkage porosity. This is not always taken into account when creating a CAD model of a casting and a mold, therefore, after loading the mesh model into the Master module, it may be necessary to change its orientation. In this case, it is necessary to fix the visual angle of rotation, i.e. enter it into the real coordinates of the GM. The corresponding commands are located on the Transformation Toolbar.

Remember that when you rotate the object (s) in the working area (see the Common Elements of 3D Modules section), the view or the viewing angle of the model changes, but the orientation in the coordinate system remains the same, because the coordinate system rotates with the object..

|

Click the Reset Rotations button on the Rotations toolbar to set the model to a base position: the X-axis is horizontal, the Y-axis is vertical, and the Z-axis is perpendicular to the plane of the screen. This position corresponds to the front view. |

In the base position, it is clear how the model is oriented in the PoligonSoft coordinate system. For example, on Fig. below (left) you can see that the loaded model is oriented incorrectly. For convenience, you can turn off the display of form volumes in the model tree. Use the buttons on the Rotations toolbar to set the correct position of the model. For example, for the case shown in Fig. below (left), you need to double-click the Rotate Across X 90° button to rotate the model 180° around the X axis.

Do not use the mouse to rotate the model! Adjusting the exact position with the mouse "by eye" is not possible. Use the buttons on the Rotations toolbar.

|

After the model is in the correct position on the screen, click the Fix Rotation button on the Transformation toolbar. |

When you click on the Fix Rotation button, the position of the object in the working area will remain unchanged, but the coordinates of the mesh nodes will be recalculated, and the coordinate system will unfold to the base "front view" position (see the figure below on the right). Now the direction of the gravity vector (against the Y-axis) corresponds to the technological process.

|

|

|

Front view before rotation |

Front view after rotation |

The result of the coordinate system rotation

In some cases, additional editing of the model may be required, for example, its scaling or mirroring about one of the axes.

Mirroring the Model

In some cases, it is necessary to mirror the geometric model along an axis. This means that the coordinates of all points along this axis will be reversed. To do this, use a group of three buttons on the Transformation toolbar.

|

The Reflect by X command flips the geometry around the X axis. |

|

The Reflect by Y command flips the geometry around the Y axis. |

|

The Reflect by Z command flips the geometry around the Z axis. |

Press the desired button on to get the result. If the wrong button was selected by mistake, you must press it again to return the model to its original position. In Fig. below is the result of flipping the model along the Y axis.

|

|

|

Before reflection |

After reflection |

The result of flipping the model along the Y axis

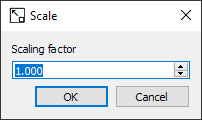

Scaling the Model

Sometimes you need to change the dimensions of the model. Most often, such a need arises if the units of measurement were specified incorrectly when importing the mesh (for more information, see the Loading and saving the model section).For the dimensions of a model, see the Model Information section.

|

The Scale button on the Transformation toolbar opens a dialog where you can set the scaling factor of the model (see the figure below). |

Scale Dialog

Enter the desired value in the Scaling factor field and click the OK button. You can control the result in the Model Information window.

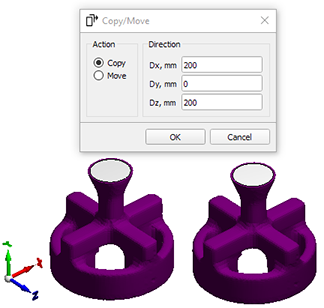

Copying and moving model volumes

You can create copies of one or more model volumes or move these volumes in a given direction. This can be useful, for example, when modeling the filling of several identical molds standing side by side. In this case, there is no need to create mesh models for all molds.

|

The Copy/Move button on the Transformations toolbar opens a dialog where you can set the direction of copying or moving the visible volumes of the model (see figure below). |

Copying the casting and shell volumes with a shift along the x and z axes

In the left part of the dialog, select the action to be performed. In the right part of the dialog, you need to enter the components of the displacement vector in mm. Clicking the OK button will complete the operation.

Note that the action is performed only for visible objects (visibility is set in the model tree). It should be noted that the intersection of grids is not allowed.

Measurements

|

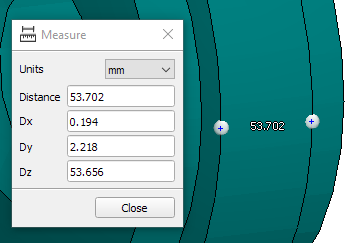

The Measure (F4) button opens a tool for measuring the distance between two given points (see figure below). |

Measuring the distance between two points

To put a point, you need to right-click while holding down the Ctrl key. After two points are set, the distance between them is shown in the drawing area. The dialog displays the length of the segment between two points and the length of its projections on the coordinate axes.

To remove a point, you need to click the left mouse button while holding down the Ctrl key.

Materials Assignment

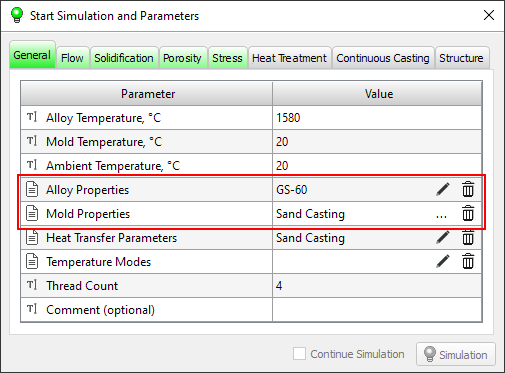

At the beginning of the loaded model set-up for calculation, it is advisable to load all the necessary materials into the project: casting material and mold materials. This can be done in the Start Simulation and Parameters window on the General tab by filling in the lines Alloy Properties and Mold Properties (see the figure below).

Start Simulation and Parameters window

At the end of each line there are icons for necessary operations are performed.

|

The button is located in the Mold Properties line and loads files of the pmms type (or the obsolete bdf type) into the project, which can contain up to 9 mold materials used for a particular casting technology. Such files can be loaded from the PoligonSoft database and edited by the user (see later in this section). |

|

The button is located in the "Alloy properties" line and opens the material editor, where the user can load the material from the PoligonSoft database or enter his own data. See the Material Properties section for details. |

|

The button removes data from the project and clears the line. |

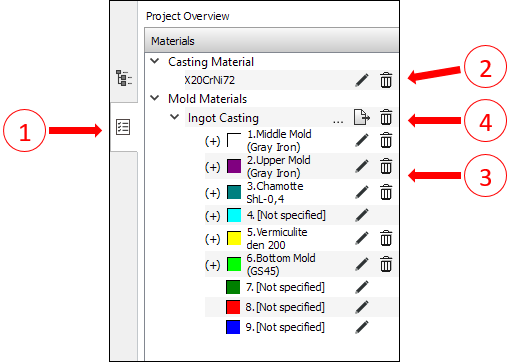

Another way to assign materials is the Materials tree, which is located on the Project Overview tab (1) in the Master module main window (see the figure below). To set the casting material, press  button in the corresponding line (2). The material editor will open and you can import the required material from the database (see the Material Properties section for more details).

button in the corresponding line (2). The material editor will open and you can import the required material from the database (see the Material Properties section for more details).

Material tree on the Project Overview tab

МThe mold materials can be specified in the same way as the casting material, i.e. importing each material for each mold volume index directly from the material database. To do this, successively press  buttons opposite each desired volume index (3) and load the material through the Material Properties editor. Volume indexes assigned to mold bodies are marked with a "(+)" sign at the beginning of the line. If desired, you can save the loaded set of mold materials to a pmms (PoligonSoft Mold Materials Set) file and then use it in other calculations, to do this use the

buttons opposite each desired volume index (3) and load the material through the Material Properties editor. Volume indexes assigned to mold bodies are marked with a "(+)" sign at the beginning of the line. If desired, you can save the loaded set of mold materials to a pmms (PoligonSoft Mold Materials Set) file and then use it in other calculations, to do this use the  button (4). Such files, created for different cast technologies, are in the PoligonSoft database, and they can be loaded with a

button (4). Such files, created for different cast technologies, are in the PoligonSoft database, and they can be loaded with a  button (loading of obsolete bdf files is supported).

button (loading of obsolete bdf files is supported).

Editing Volume Types and Indices

As described in Basic Concepts: Volumes, Types, Indexes section, in the imported mesh, finite elements are grouped in volumes according to the casting and mold design. Preparing the calculation, all volumes of the model should be assigned one of two types: "casting" or "mold". In addition, each volume is assigned a number or "index", which means that this volume is assigned some condition or property (physical parameters, temperature, etc.). These conditions and properties are set through the connection of the corresponding databases, templates and process conditions. For example, for "mold" volumes , the volume index always determines its material. The properties of this material will be assigned to the volume by the index number from the loaded mold materials property set. Below, in the table, there is a list of properties and conditions that can be assigned to the volumes of the model through the volume index. Note that this list is not the same for casting and mold volumes.

| Property / Condition | Casting | Mold |

|

Material Properties |

|

+ |

|

Temperature Mode |

+ | + |

|

Translation |

+ | + |

|

Radiation Area |

+ | + |

|

Removable element of the gating system |

+ |

|

It follows from the table that by assigning the same volume indices to the casting and mold volumes, you can set them the same conditions, for example, the temperature mode. This can have undesirable consequences, so you should carefully consider what conditions are associated with the selected index.

When importing a mesh created in a mesh generator, the first volume recorded in the file gets the "casting" type by default, all other volumes - the "mold" type. At the same time, the volumes receive continuous numbering, i.e. the first volume gets index 1, the second - 2, and so on. If there are more than 9 volumes in the model, the tenth volume will get index 1 again, and so on. In most cases, the "default" settings do not correspond to the real situation and you need to manually specify the Type and Index parameters for each model volume.

Before you start editing the types and indices of volumes, you should connect one of the templates of the technological process (for example, mold materials file) to the Master module in order to establish a connection between the indices of volumes and the materials of the mold. This is done in the Start Simulation and Parameters window on the General tab in the Mold Properties line(see details in the Сommon Simulation Parameters section). System templates for different technological processes are located in the %PoligonSoft%\Database folder.

|

In order to reassign indices or volume types, the model tree is used, which is displayed by clicking the Model Tree button in the Standard toolbar (button pressed by default). |

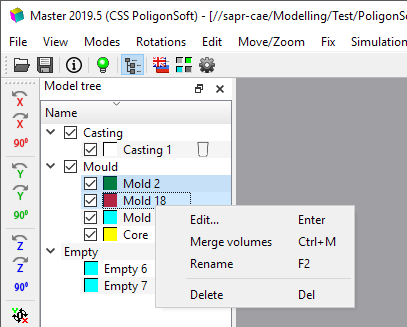

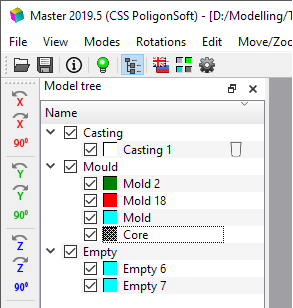

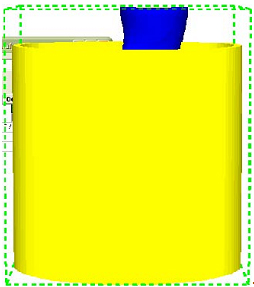

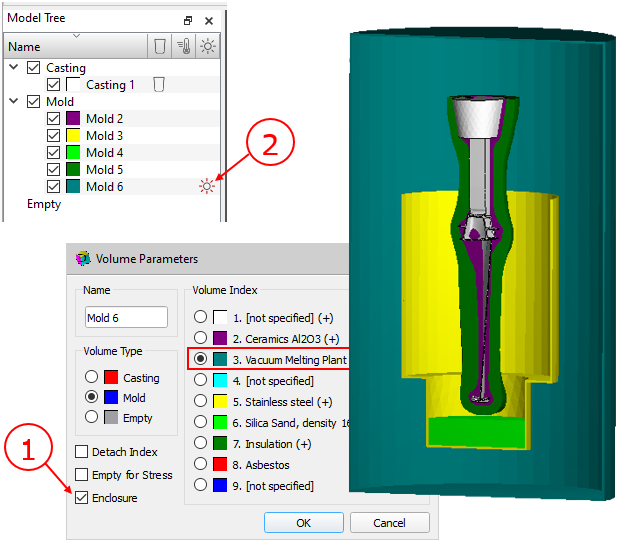

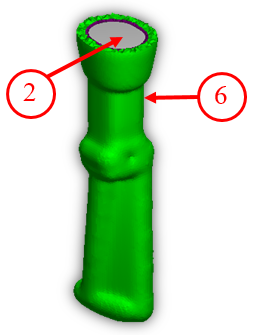

The tree contains a list of all the volumes available in the simulation area (see the figure below). The volumes are distributed in three tree branches according to the type (Casting, Mold or Empty). By default, all volumes have names according to the type to which they belong and consecutive numbering (for example, "Casting 1" "Mold 2", "Mold 3", "Empty 4").

Model Tree in the Master module

Each position in the tree has a switch that controls the visibility of the volume or the entire group of volumes. When the switch is off, the selected volume or group will not be displayed in the working area of the module. When the switch is on, a volume or a group of volumes is displayed on the workspace. The display mode is set by the buttons on the Modes panel (see details in the Model Display Modes section). The display of the volumes of the Empty group is always disabled and cannot be enabled. To display volumes from the "Empty" group, you need to change their type to Casting or Mold. Each volume in the tree has a color indicator indicating the volume index in accordance with the color scale adopted by PoligonSoft (for more information on the indices of elements (volumes), see the Basic concepts: Volumes, Types, Indices section).

To the right of the name are condition indicators. They become active if any conditions associated with its index are assigned to the volume. By clicking on the active indicator, you can edit the specified condition, this is described in the corresponding sections below.

Some of the commands described below are available through the context menu of the tree (see the figure below), the content of which varies depending on the mode of object selection - one at a time or a group one.

Context menu of the Model Tree

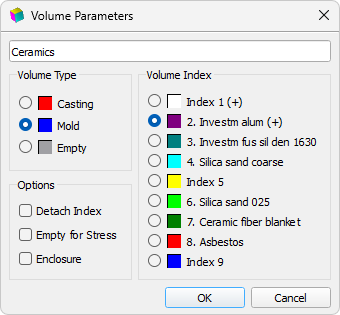

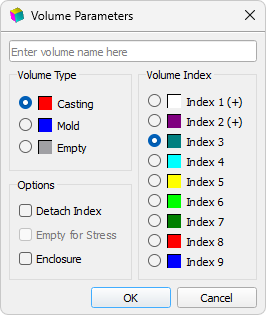

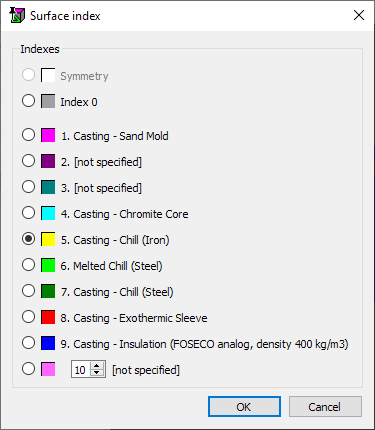

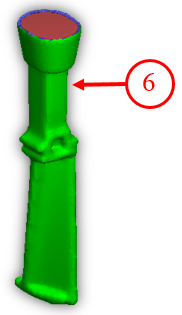

To go to volume editing, double-click with the left mouse button on its name in the model tree, or on the volume itself in the working area of the module. This will open the Volume Parameters window (see the figure below). You can change the parameters of not only each volume separately, but also a group of volumes. To do this, select the required volumes in the model tree, and then open the volume parameters window through the context menu of the model tree or by pressing the Enter on the keyboard.

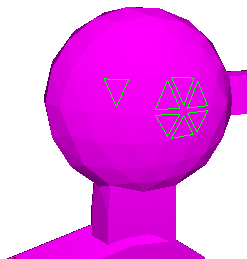

Volume Parameters window

(Investment casting technology template used)

At the top left, in the Name field, the name of the edited volume is indicated, which can be changed. Three radio buttons on the left side of the window allow you to change the type of volume, and the nine radio buttons on the right - its index. The plus sign (+) to the right of the index number indicates that this index has already been assigned to some volumes of the model. This does not prevent you from applying this index again, the model may contain several volumes with the same index (for example, if they are made of the same material).

The figure above shows the view of the window for editing the volume parameters when the volume type "Mold" is selected. In this case, the volume index always specifies the volume material of the mold, so the material names are written next to the indexes. The list of materials and the correspondence of these materials to indexes are set by the user on the Project Overview tab independently by loading materials from .pmat files or by loading a process template, i.e. mold materials file .pmms (for details, see the Materials Assignment section). If the volume type is Cast or Empty, the volume index list does not contain useful information. In general, casting bodies can have any indices , because usually they are not given special conditions or special technological parameters. However, in some situations (for example, when using internal chills), the volume index of the casting can be important. This is discussed in the relevant sections.

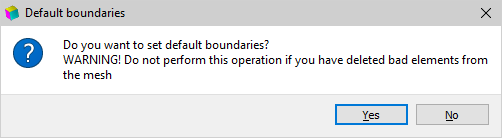

Changing the volume parameters is completed by pressing the OK button. If the volume type was changed during editing, a message will be displayed prompting you to assign default boundaries (see the figure below). This happens because after the volume type changing , the numbering of its boundaries contradicts the accepted "standard" indexing of the outer borders (by default, these are indices 17 and 18). The default numbering of boundaries is discussed in the Basic concepts: Volumes, Types, Indices section. The operation of assigning the default boundaries usually facilitates the preparation of the model, but in some cases it is undesirable (for example, when deleting "bad" elements, see the section "Mesh Quality Control" about this). If you agree to assign the default boundaries, you need to click the Yes button, otherwise, click No.

Message prompting to assign default boundaries

If you want to change only the type of volume or volumes (without changing their indices), you just select these volumes in the tree and drag them to the desired group.

By default, the "Master" establishes none-ideal contact at the casting-mold interface and ideal contact between the mold volumes. In other words, the casting and mold are FE mesh with coincident nodes at the contact boundary. Bodies of the "Mold" type represent a equivalent mesh, the elements of which can have different properties, depending on which index is assigned to them. You can split the meshes of mold bodies so that a mold-to-mold boundary forms between them, where you can set the heat transfer conditions (none-ideal contact). To do this, select the detachable volume in the model tree, double-click the window to edit the volume parameters, and tick the Detach Index checkbox located under the Volume Index group. After pressing the OK button, indices corresponding to the required heat transfer parameters can be assigned to the boundaries of the separated volume (the procedure for assigning these parameters is described in the Heat Transfer Parameters section). The color indicator of the separated volume has a tick image in the Model Tree (see the figure below).

View of the Model Tree with separated volume (yellow)

Additional volume control commands are available through the context menu of the tree:

- Merge Volumes. The command combines the selected volumes into one, provided that there is a contact between them. If there are the volumes among the selected one that do not touch any of the group's volumes, a corresponding message will be displayed. At the same time, if the merger process continues, the adjacent volumes will be merged. During the merge process, a window for editing volume parameters opens, where you can specify the name, type and index of the new volume, and, if necessary, separate it. By default, the new volume is being assigned a name consisting of the names of the volumes to be merged, for example: mold1-mold2-mold3. You can use the key combination Ctrl + M on the keyboard to call the command.

- Rename. The command opens access to editing the name of the volume selected in the tree. You can use the F2 key on the keyboard to call the command.

- Delete. The command removes the selected volume from the model permanently. You can use the Delete key on the keyboard to call the command. If you are not sure about the need to delete the volume, you can temporarily move it to the Empty group, it will remain in it as long as the file is open.

|

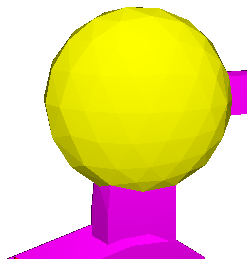

To see the results of the Type assignment, you should enable the coloring of the model by volume types by clicking the Show Volume Types button on the Modes panel. |

|

To see the results of assigning the Element Indices, you should enable the model coloring by the volume indices by clicking the Show Volume Indices button on the Modes panel. |

More details about display modes see in the Model Display Modes section.

Editing Element Indices in the Arbitrary Areas

Sometimes it is necessary to change the model, for example, delete fragments of some volumes or assign new properties to some arbitrary area of it. Typically, this requires changes in CAD and create a new FE model in the mesh generator, but in some cases, these operations can be avoided. To do this, it is possible to create a new volume from an arbitrary group of elements and assign the necessary parameters to it: type and index, in Master module. The concepts of "type" and "index" of an element are described in the Basic concepts: Volumes, Types, Indices section.

To select elements, use a group of buttons on the Edit toolbar (see the figure below). Some of the buttons in this group may be inactive if there are no selected elements in the model.

Buttons for element indices edition

To create a new volume within the existing model, you need to select the required group of elements and assign new parameters to it.

|

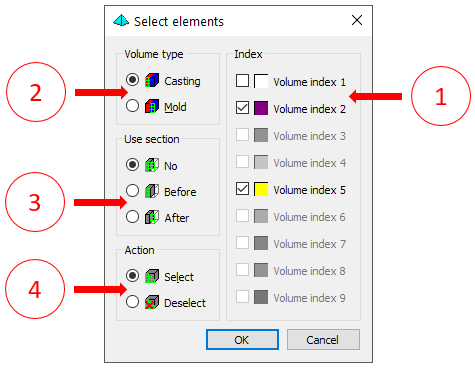

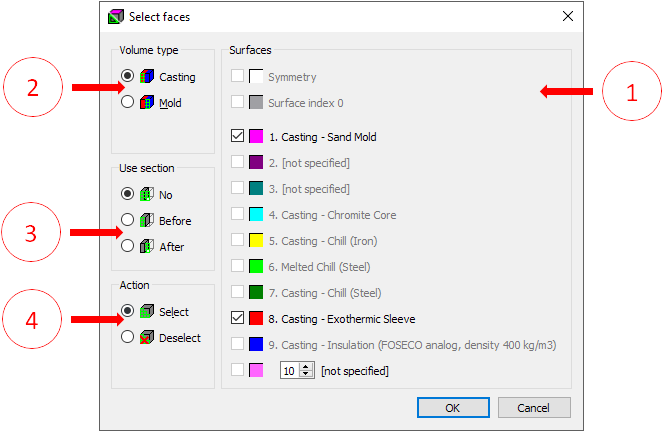

The easy way to select elements is to use Select Elements button. This opens the dialog box (see the figure below), where you can use the checkboxes and radio buttons to describe the group of elements that you want to select. |

Select Elements Dialog

To select elements of one or more indices, you need to check the corresponding lines in the right part of the window (1). Only those volume indices that are used in the model are available for selection. The radio buttons (2) indicate where to select the elements of the selected indices - in the casting or in the mold. Depending on the selected volume type (2), the list of volume indices available for selection (1) changes. Radio buttons (3) set how to select elements, selected (1) indices and located in specified (2) volumes, in relation to the section plane. Either all elements satisfying conditions (1) and (2), or their part located before or after a given section plane can be marked. To use condition (3), you must first set the section plane to the desired position. How to control the section is described in the Section Plane section.

Finally, the radio buttons (4) set the operation on a given group of elements - select or deselect.

It should note, that an element is considered to be located on any side of the section plane if all four of its vertices are located there.

After the group of elements is set, click the OK button in the Select Elements dialog to apply the selection operation.

|

Another quicker way to select elements is to select it by frame. To activate this method, you should click Select Elements by Frame button. The button will remain pressed. |

It should be noted that the selection of elements in an arbitrary way, without relying on the types and volume indices assigned to them, can be a rather laborious procedure.

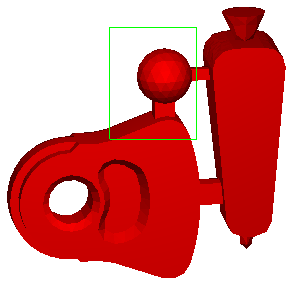

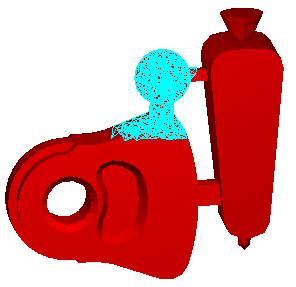

When the pressed button Select Elements by Frame, the combination Shift+LMB allows you to stretch a frame of the required size in the working area (see the figure below). All elements that are entirely within the frame area will be selected. The selection result is shown in Fig. below. This operation can be repeated several times to obtain the desired result.

|

|

a) |

b) |

Selection of a group of elements with a frame: a) selection area; b) result

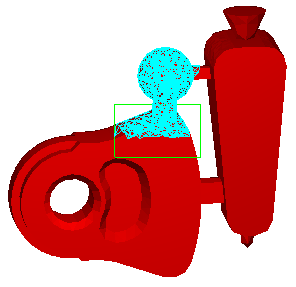

The Shift+RMB combination allows you to set an area with a frame to deselect a part or all selected elements (see the figure below). All elements that fall entirely within the frame area will be deselected. This operation can be repeated several times to obtain the desired result.

|

|

a) |

b) |

Canceling the selection of a group of elements with a frame: a) selection area; b) result

The appearance of the marked elements (tags) is determined by the settings (see the Mark Parameters section).

|

The selected elements can be assigned a new index and other parameters. To do this, click the Assign Volume Index button on the editing panel. The Volume Parameters dialog will open (see the figure below). |

Volume Parameters Tool

In the Volume Parameters dialog, you can assign a name, type and index to a group of selected elements. After pressing the OK button, a new volume will appear in the model tree, and the selection will be canceled.

Other operations with volumes are described in the Editing Volume Types and Indices section.

|

All available marks can be removed by clicking the Deselect All Elements button on the Edit toolbar or using the Ctrl+E hotkeys. |

|

To see the result of assigning indices to selected elements, you can turn on the GM visualization by volume indices by clicking the Show Volume Indices button on the Modes panel. This is described in more detail in the Model Display Modes section. |

Editing Boundary Indices

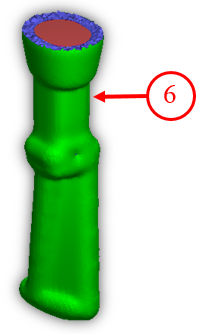

All faces of the elements of each GM volume numbers or indices are assigned . Faces forming surfaces (boundaries) with the same heat transfer conditions are combined under one index. It can be both internal body-body boundaries, and external body-environment. In total, 19 indices can be assigned to the faces of finite elements, they are numbered from 0 to 18. Index 0 is automatically assigned to the inner faces of elements of the same type (casting-casting and mold-mold), it is also assigned to the boundaries of symmetry. Indexes in the range from 1 to 9 can be assigned to the boundaries between bodies with imperfect contact (casting-mold, mold-mold) or external boundaries. Indexes in the range from 10 to 18 can only be assigned to the outer boundaries of bodies (casting-environment and mold-environment boundaries). For more details see the section «Basic concepts: Volumes, Types, Indices».

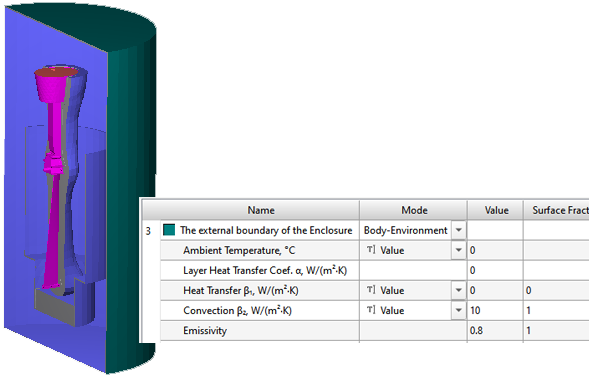

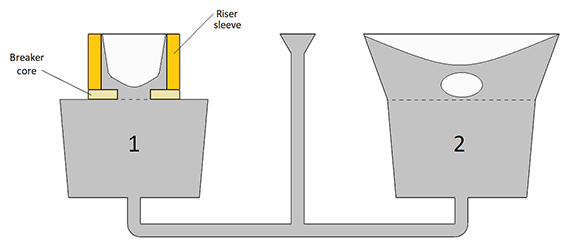

According to the index, boundary conditions are assigned at the border, which are connected to the project through heat transfer files, temperature modes and other files of simulation conditions. For example, to simulate any casting technology, you need a heat transfer parameters file that defines the heat transfer conditions at the boundaries between bodies and at the outer boundaries. When loading the model, the Master module automatically assigns indices to the boundaries according to a certain scheme, which is suitable for modeling most casting technologies: the boundary between the casting and the mold gets the index 1, the boundary between the casting and the medium gets the index 17, the boundary between the mold and the environment - the index 18. Under this scheme is set up by templates of foundry technologies supplied with PolygonSoft. To understand the relationship between the boundary index and the corresponding boundary condition, before you start editing the boundaries, you need to connect the * .afo heat transfer file from the PolygonSoft database to the project. The %PoligonSoft%\Database folder contains such files with heat transfer settings for different technological processes. See Сommon Simulation Parameters section for details how to connect a heat transfer file to a project.

Quite often, automatically assigned boundary conditions (boundary indices) do not reflect the real situation. For example, for sand mold casting, the boundary between the casting and the mold will automatically get index 1. When using a heat transfer file for this type of casting, the heat transfer conditions at boundary 1 will be set correctly. But if a steel or cast-iron chill is installed in the mold, the boundary between the chill and the casting will also have an index 1 by default. Obviously, this is wrong and this situation should be corrected. In the file of heat transfer parameters * .afo for sand casting, there are preset conditions for heat transfer between the casting and the chill, but they have a different index. Therefore, you should select the surface between the casting and the chill and change its index to the correct one.

Operations related to the selection of elements faces are performed using the group of buttons on the Edit toolbar.

Buttons for working with boundarie

|

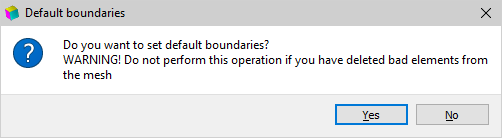

Automatic boundary indexing can be performed by clicking the Set Default Boundary Indices button. For more information on default (or standard) boundaries, see Basic concepts: Volumes, Types, Indices section. After pressing the button, a warning is displayed (see the figure below). |

Warning when assigning default boundaries

The offer to load default boundaries automatically appears when changing the volume type.

The user can make changes to the default boundary indexing scheme by introducing boundaries with other indices, if necessary, in order to set special boundary conditions for some sections of the boundaries. There are two ways to do this in the Master module.

|

The easiest way to select borders is to use the Select Boundaries button. This opens a dialog box (see the figure below), in which you need to set the signs of the boundaries that need to be selected. |

Select Boundaries Dialog

To select the boundaries of one or more indices, check the corresponding lines in the right part of the window (1). Only those boundary indices that are used in the model are available for selection. Borders with indices 10-18 are checked using a special edit box with arrows. Radio buttons (2) indicate where to select the boundaries of the selected indices - in the casting or in the mold. Depending on the selected volume type (2), the list of boundaries indices available for highlighting (1) changes. Radio buttons (3) set how to select boundaries, selected in (1) indices and located in specified (2) volumes, in relation to the section plane. Either all boundaries satisfying conditions (1) and (2), or their part located before or after a given section plane can be selected. To use condition (3), you must first set the section plane to the desired position. How to control the section plane is described in the Section Plane section.

Наконец, радиокнопки (4), задают саму операцию над заданной группой границ – выделить или отменить выделение.

It should be note that the face of an element is considered to be located on one or another side of the section plane if all three of its vertices are located there.

After the conditions are set, click the OK button in the Select Boundaries dialog to perform a selection of the boundaries.

Another way to select boundaries is interactive, using the left mouse button and holding down the Ctrl key. In this way, you can select either single element faces or entire surfaces.

|

Switching between selection modes is carried out by the Select Contiguous button on the Edit toolbar. |

If the button is not pressed, the outer edges of the elements are selected one at a time (see the figure below). When the Select Contiguous button is pressed, a mouse click with the Ctrl button pressed will select the entire surface (see the figure below). To deselect individual faces or surfaces use the right mouse button while holding down the Ctrl key.

|

|

Selecting individual faces |

Surface selection |

Boundaries selection

When the Select Contiguous button is pressed, a surface is considered to be a set of adjacent faces, where the dihedral angle between adjacent faces is not less than the specified value in the range from 0 to 180 degrees. For example, if you set this angle to 180°, the adjacent faces that lie in the same plane will be selected, and if the value is 0°, all the faces of the volume will be selected. The default surface angle is 150°.

|

The angle value for the surface, as well as the appearance of the marked boundaries, can be set in the Settings window on the Mark Parameters tab, which is opened by the Mark Parameters button on the Edit toolbar (for more details see Mark Parameters section). |

|

The marked boundaries can be assigned a new index. To do this, click the Assign Boundary Index button on the Edit toolbar. The Boundary Index dialog will open (see the figure below). |

Boundary Index Dialog

Select the desired item in the list, then press the OK button. The marked boundaries will be assigned the selected index and deselected (see the figure below).

The result of replacing the index of the selected boundary part

|

All borders can be deselected either by clicking the Deselect All Boundaries button on the Edit toolbar, or by using the Ctrl+G keyboard shortcut. |

|

To see the result of assigning boundary indices, you can turn on the GM rendering by boundary indices by clicking the Show Boundary Indices button on the Modes toolbar (see details in Model Display Modes section). |

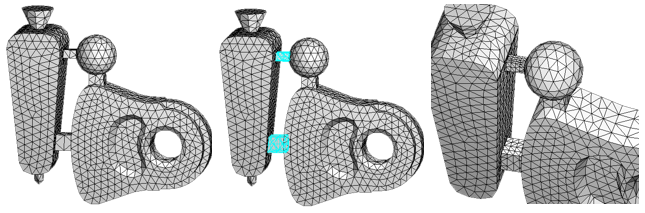

Mesh Quality Control

Mathematical models used in PoligonSoft impose rather stringent requirements on the quality of meshes, therefore, quality control of elements is an important task of preparing a model for calculation. Ideally, all elements of a tetrahedral finite element mesh should have the shape of a regular tetrahedron, i.e. to the tetrahedral pyramids, consisting of equal equilateral triangles. In practice, this is unattainable, but it should be ensured that the grid does not contain elements with a highly distorted shape - the grid must be fairly regular. In addition, elements whose volume is zero or close to zero - the so-called degenerate elements - are unacceptable. The presence of even one degenerate element can make the calculation impossible. Therefore, the Master module contains functions for improving the overall quality of the mesh and correcting individual "bad" and degenerate elements. In practice, correction of the shape of an element can almost always be done only at the expense of degrading the quality of the elements surrounding it. Therefore, the algorithms for correction cannot be applied to a large number of elements at the same time. And vice versa - regularization algorithms are effective only when there are a large number of vertex elements (i.e. mesh nodes) which can be freely moved.

Mesh quality control and the correctness of the elements is maintained by a group of buttons on the Edit toolbar.

Buttons for the work with the mesh quality

A "bad" element is one that has too small and/or too large dihedral angles. Both mean that the shape of the element is far from correct, it is degenerated almost to a flat figure. Such an element will not be accepted for calculation in the Fourier and Hooke solvers. In addition, solvers impose a number of size requirements on finite elements and the ratio of volume and surface values. These requirements are dictated by the numerical calculation method, they cannot be changed.

|

To edit the limit values for the angles of elements that determine the quality of the mesh, click the Mark Parameters button on the Edit toolbar (for more details, see the Mark Parameters section). |

|

The simplest and at the same time favor way to improve the quality of the mesh as a whole is the performing the Regularization function on the Edit toolbar. |

With regularization, an attempt is made to bring the shape of all finite elements of the model closer to a regular tetrahedron. If the task of the functions of correcting "bad" elements (discussed below) is to avoid their presence even at the expense of some deterioration in the shape of neighboring elements, then the main task of regularization is to improve the quality of as many elements as possible without deteriorating the quality of others. In addition, during regularization, the nodes lying on the boundaries of the volumes, on the position of which its shape depends, remain stationary.

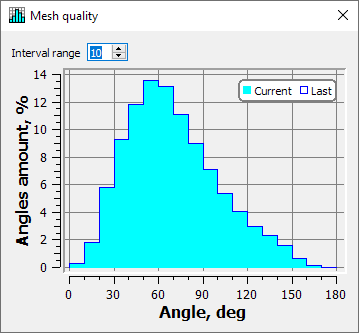

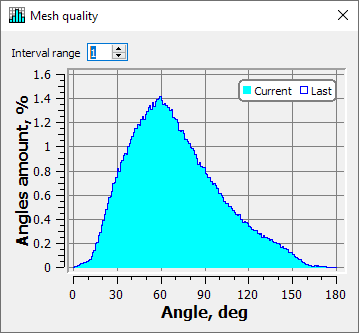

Regularization can be performed multiple times and the mesh quality can be improved. The function works automatically, without user intervention. You can evaluate the results of regularization by the quality histogram, which appears automatically upon completion of the operation (see the figure below).

The mesh quality histogram shows the percentage distribution of finite element dihedral angles over angle intervals. The width of the interval can be changed using the field located above the histogram from 1 to 60 degrees.

Mesh quality histogram with 10 degree and 1 degree angles interval

The filled columns show the distribution of dihedral angles after regularization, and the outlines show the distribution of dihedral angles before regularization. The legend is shown in the upper right corner of the diagram. In a good quality mesh, most of the dihedral angles should be close to 70 degrees in magnitude. The diagram is refreshed each time the regularization is performed.

The color of the columns of the chart is the same as the color of the element marks. To change the color of the diagram, use the Special Colors button on the Standard toolbar (for more details see Special Colors section).

|

The angle distribution histogram can be viewed by clicking the Mesh Quality button on the Edit toolbar. |

Another way to improve the quality of the mesh is to reshape only the bad elements. In this case, the algorithm automatically moves the mesh nodes, trying to eliminate invalid geometric parameters in individual, selected mesh elements.

|

To find and select bad elements with angles outside the limit values, you should execute the Check Mesh Quality command on the Edit toolbar. |

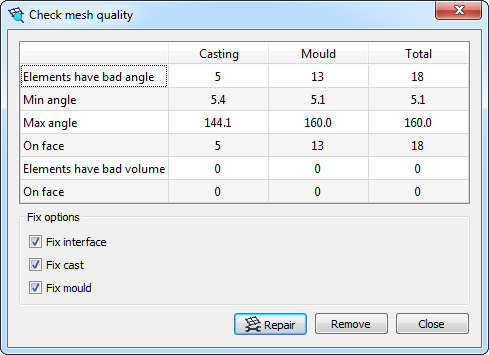

When the command is executed, it starts checking the angles and volumes of the casting and mold elements. Then the Check Mesh Quality dialog opens (see the figure below) and the check results are displayed in the table.

Check Mesh Quality Dialog

The first column shows information about the mesh quality of the "casting" type bodies , the middle column shows information about the mesh quality of the "mold" type bodies, the third (right) column of the table shows summary information.

For each type of volume, the table shows the following information:

- the number of elements with dihedral angles outside the range of permissible values;

- minimum and maximum values of dihedral angles in elements;

- how many elements with dihedral angles that go beyond the limits of permissible values are located on the outer boundaries of the volumes;

- the number of elements with degenerate volumes;

- how many degenerate elements are located on the outer boundaries of the volumes.

Found bad elements will be selected (marked) in accordance with the previously set label parameters (see the figure below).

An example of highlighting bad elements after checking the mesh quality

The correction of the marked bad elements is started by clicking on the Repair button in the Check Mesh Quality dialog.

The correction process is a responsible operation, since the movement of grid nodes applies to any "bad" elements of the model, including those located on the boundaries. This means that the operation may distort the shape of the object. Therefore, in the lower part of the Check Mesh Quality dialog, there are options for the algorithm for correcting elements (more precisely, shifting mesh nodes). By enabling and disabling the corresponding parameters, you can choose where to allow the displacement of nodes (in the casting, in the mold) and enable or disable the displacement of nodes at the boundaries. The last option allows you to keep the shape of the bodies without distortion.

It should be note that the maximum effect can be obtained when all types of fixes are allowed (enabled by default). The only drawback is the possible distortion of the boundaries of the casting or mold. It is better to run the simulation with some geometry inaccuracies than rebuilding the finite element mesh.

Correction of elements ends with a message (see the figure below). The information in the table of the Check Mesh Quality dialog will be updated.

Mesh repair completion message

If, after correcting the elements, the information in the table shows that not all elements with bad angles or degenerate volumes have been corrected, it is advisable to repeat the correction procedure again. It should be repeated as long as the number of detected "bad" elements continues to decrease. If after the next cycle the number of "bad" elements has not decreased, further attempts will be useless.

Elements that could not be repaired can be removed from the model. To do this, press the Delete button in the Check Mesh Quality dialog. After confirming the operation (see the figure below), the marked elements are deleted from the geometric model without the possibility of restoration.

Deleting elements operation confirmation

Thus, there will be no more bad elements in the model, but the model itself will slightly lose its geometric accuracy.

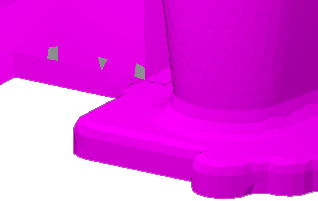

Attention! Removing bad elements from the model should be done only after the volume types have been specified and the correct bounding indices have been assigned.

When bad features are removed, the faces of adjacent features become external. However, these faces will have an index of 0 (inner face, see the figure below), which contradicts the accepted "standard" indexing of outer boundaries (usually these are indices 17 and 18). The standard numbering of borders is discussed in the Basic concepts: Volumes, Types, Indices section.

Boundaries with index 0 (gray) in places where bad elements are removed

If, after removing bad elements from the model, you change the type of any volume, you will be prompted to assign “standard” boundary indices to all volumes. This can have irreversible consequences. you cannot assign standard boundaries after deleting "bad" elements, so you should click the No button in the message box. If you click Yes, outer boundaries appear in the body of the casting or mold where the feature was removed, resulting in incorrect calculation of temperature fields in that area. It is important to preserve the outer boundaries with the index 0 in such places, this minimizes the calculation error, the system will assume the presence of a virtual element beyond such a boundary.

If, after removing "bad" features, gray faces appear on the outer boundaries of the casting or mold, you can optionally assign them indices of the boundaries with the environment using the tools described in the Editing Boundary Indices section.

|

Additional options for transforming finite elements are provided by the Split Elements command on the Editing toolbar. It becomes available after selecting any group of finite elements and opens the Split Elements dialog (see the figure below). |

Split Elements Dialog

In the window, you can select one of two schemes for the selected mesh elements.

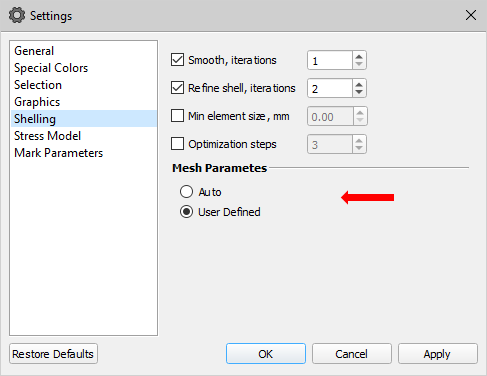

- Create nodes on element edges option divides each selected element into 8 smaller elements. The new nodes are located at the midpoints of the edges of the selection. This scheme is basic and cannot be turned off.